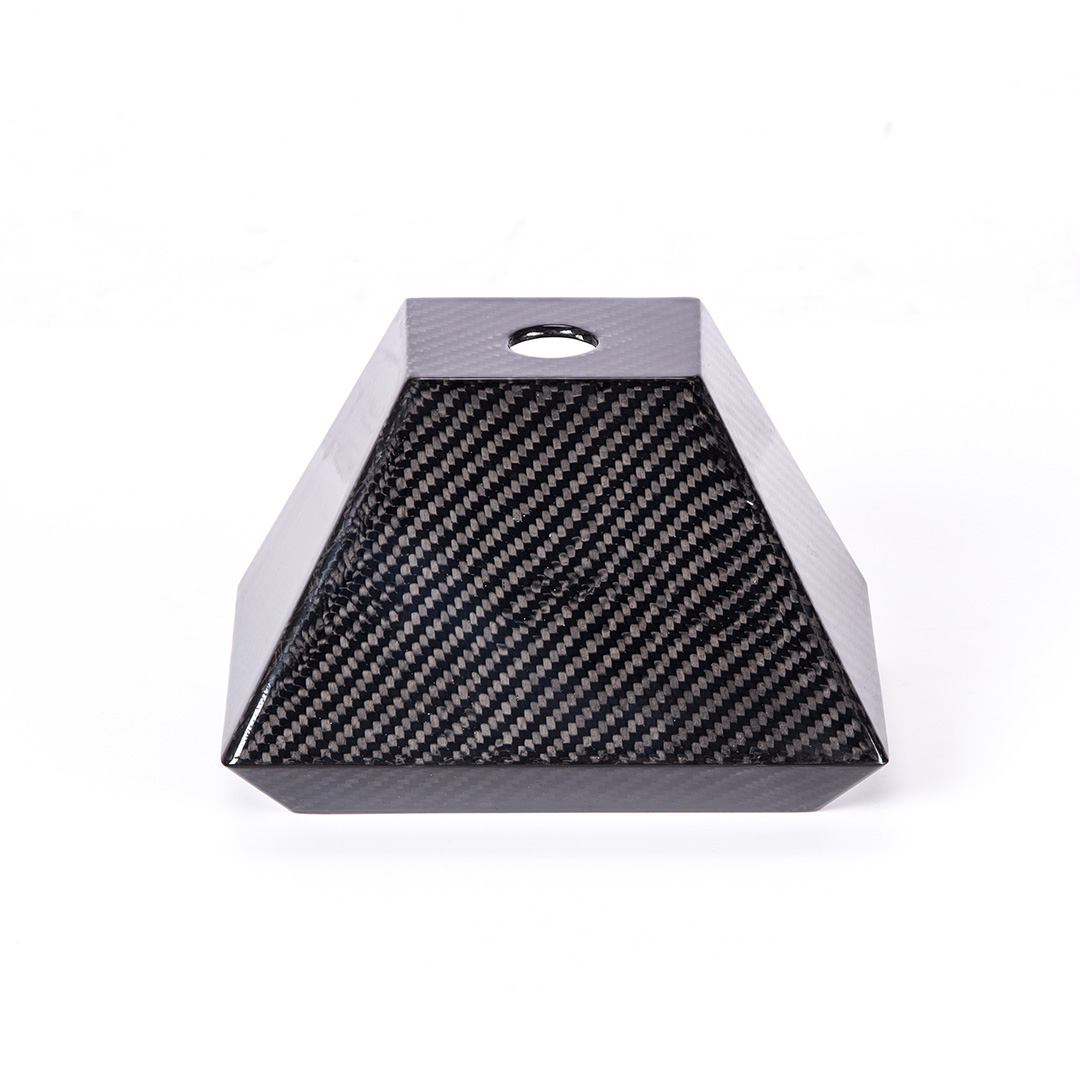

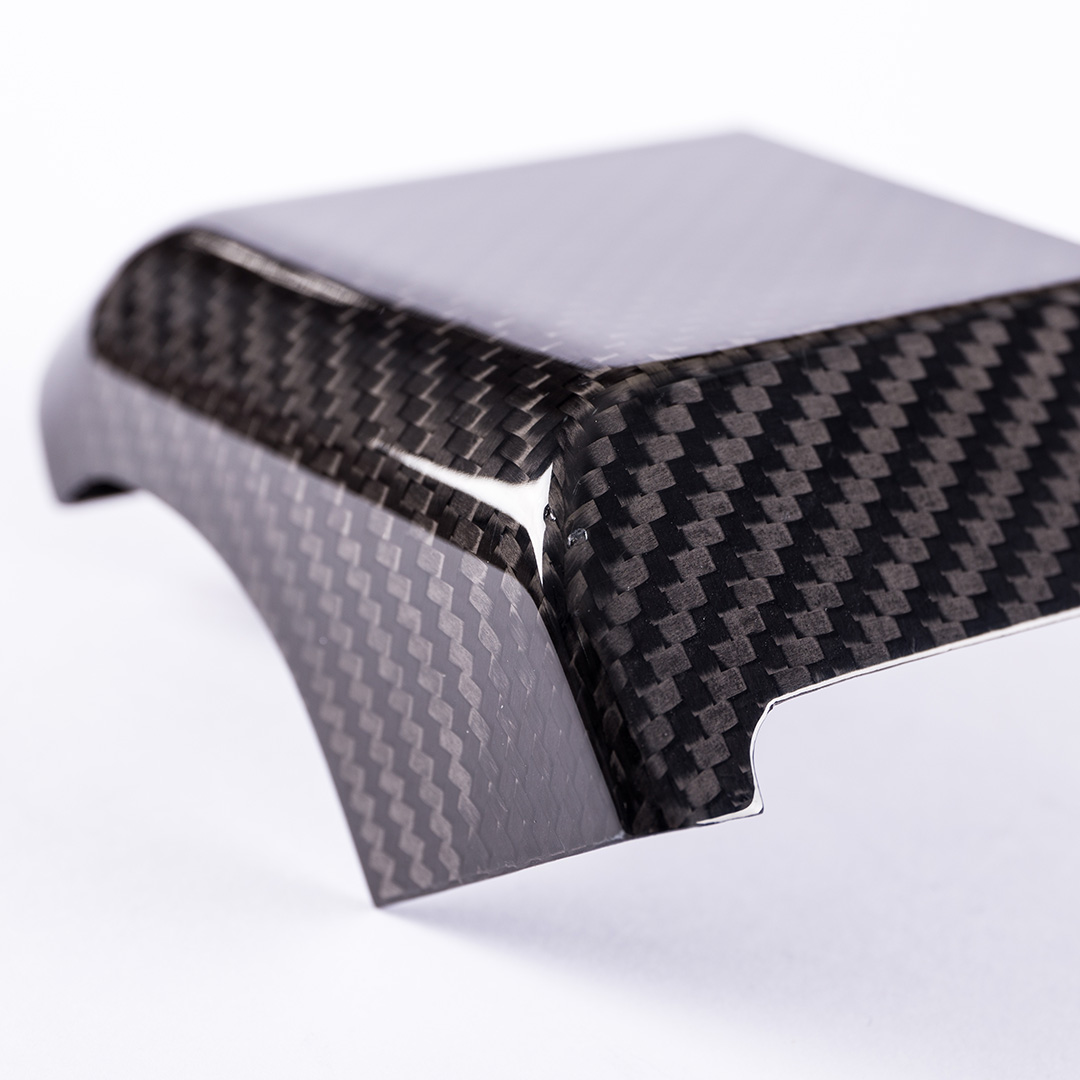

Custom carbon fiber molded product

Carbon fiber product molding process is divided into molding method, hand paste layer method, vacuum bag hot pressing method, winding forming method, and garbage molding method.

Carbon fiber molding method is mainly through the press machine and metal mold in high-temperature and high-pressure conditions. Carbon fiber prepreg molding.

The prepreg is made of carbon fiber yarn, epoxy resin, release paper, and other materials, through the coating, hot pressing, cooling, film, coiling, and other processing materials made of carbon fiber prepreg, also known as carbon fiber Dipped cloth. The reason why called prepreg is that this is only the initial impregnation of resin and carbon fiber in the product is the final shape of the reasons for impregnation.

Need a custom part? Start with a sketch or CAD file—most manufacturers work with you to refine the design and get it production-ready.

Carbon fiber custom molded products are tailored components made by shaping carbon fiber-reinforced composites into specific forms. These parts are designed to solve problems where traditional materials fall short, like when you need something lightweight, incredibly strong, or resistant to harsh conditions.

How It Works (Simple Steps):

- Design: Share your 3D model, sketch, or prototype. Engineers optimize it for carbon fiber layup and molding.

- Mold Creation: A custom mold is made (often from aluminum or composite) to match your design.

- Layup & Curing: Carbon fiber sheets are layered into the mold with resin, then cured under heat/pressure for strength.

- Finishing: Trimmed, sanded, and coated (if needed) for a smooth, ready-to-use part.

Where It’s Used (Real Examples):

- Auto/Motorcycles: Custom air intakes, dash panels, or lightweight brackets to boost speed and efficiency.

- Industrial: Corrosion-resistant guards, robotic arms, or sensor housings for factories.

- Consumer Goods: Durable drone frames, camera gear, or high-end bike components.

- Repairs: Reinforcing worn machinery parts instead of replacing them entirely.