Carbon fiber isn’t just about the material — it’s also how you lay it out. The orientation and stacking of fibers, known as the carbon fiber layout, play a crucial role in determining strength, stiffness, and performance.

Key Principles of Carbon Fiber Layout

1️⃣ Fiber Orientation

Carbon fiber is anisotropic — strongest along the fiber direction and weaker across it. That’s why layer orientation is critical:

- Load Alignment: Fibers carry loads along their length. Align layers with expected stress to maximize strength.

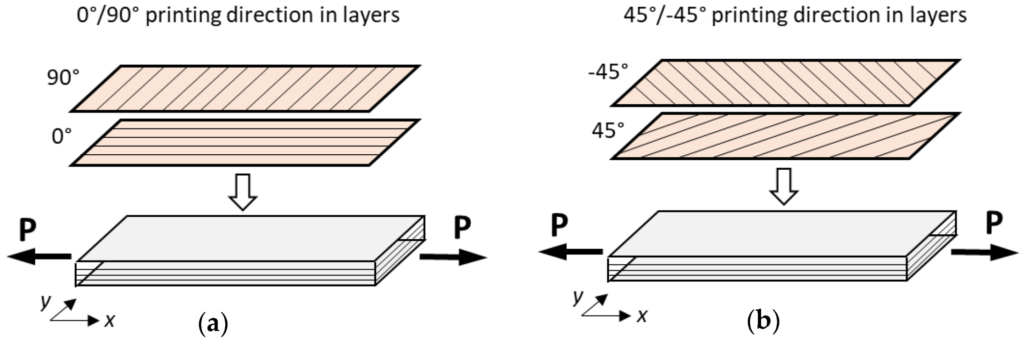

- Multi-Directional Loads: Most parts experience bending, torsion, and shear. Using layers at 0°, 90°, or ±45° distributes strength across directions.

- Torsion & Flexibility: ±45° layers resist twisting, while 0°/90° layers resist bending, balancing stiffness, torsion resistance, and durability.

2️⃣ Layering Strategy

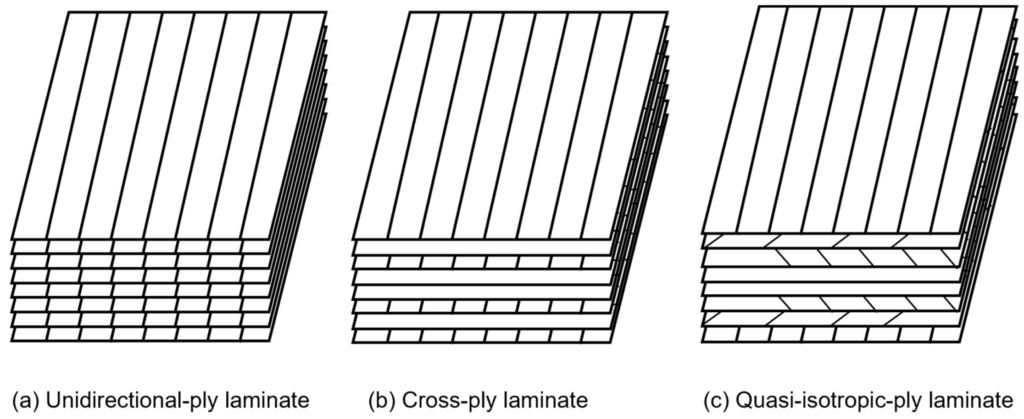

Carbon fiber parts are built by stacking multiple layers (plies). The two most common approaches:

- Cross-Ply / Bidirectional (0°/90°): Alternating layers provide strength in two perpendicular directions. Ideal for flat panels, automotive parts, and structural sheets.

- Angle-Ply / Quasi-Isotropic (±45°): Layers improve torsional rigidity and distribute loads evenly. Used in bicycle frames, shafts, and parts under complex stress.

3️⃣ Real-World Applications

Proper stacking ensures parts perform reliably under real-world conditions.

- Bicycle Frames: Angle-ply (±45°) layers resist torsion while keeping weight low.

- Automotive & RC Panels: Cross-ply (0°/90°) stacking provides bending stiffness and impact resistance.

- Shafts & Rods: Hybrid or quasi-isotropic layups handle twisting and complex loads efficiently.

✅ Key Insight Carbon fiber isn’t “one-size-fits-all.” The right fiber orientation and stacking sequence are just as important as the material itself, ensuring strength, stiffness, torsion resistance, and long-term performance — all while keeping weight minimal.

💬 Next Step– Have a project in mind? PCX Composite can help design the ideal fiber layout for your parts — balancing strength, weight, and functionality.