Carbon fiber is everywhere — from drones in the sky to cars on the road, yachts on the water, and even the phone in your hand.

But here’s the thing: not all industries use the same carbon fiber. The choice depends on strength, stiffness, surface finish, cores, and of course, cost.

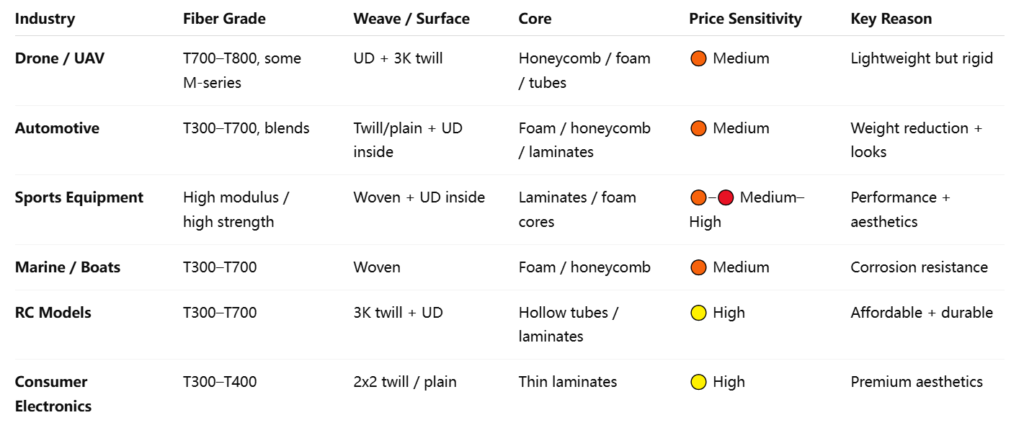

Here’s a quick industry breakdown (also chart)👇

🛸 Drone / UAV

- Fiber Grade: High strength & stiffness (T700–T800, sometimes higher modulus)

- Weave: UD for arms/frames, 3K twill for visible parts

- Core: Honeycomb, foam, hollow tubes

- Why: Lightweight yet rigid for flight efficiency

🚗 Automotive

- Fiber Grade: Mid-to-high strength (T300–T700), sometimes blended with glass fiber

- Weave: 2×2 twill/plain weave outside, UD inside

- Core: Foam or honeycomb panels

- Why: Balance between weight reduction, looks, and cost

🎾 Sports Equipment

- Fiber Grade: High modulus (golf/fishing) or high strength (bikes, rackets)

- Weave: Visible woven layers + UD inside

- Core: Solid laminates / foam cores

- Why: Lightweight, durable, and performance-driven

⛵ Marine / Boats

- Fiber Grade: Mid-strength (T300–T700), saltwater resistant

- Weave: Woven for toughness + aesthetics

- Core: Foam or honeycomb

- Why: Strong, light hulls with corrosion resistance

🎮 RC (Remote Control Models)

- Fiber Grade: Mostly mid-strength (T300–T700)

- Weave: 3K twill for looks, UD plates/tubes for structure

- Core: Hollow tubes / solid laminates

- Why: Lightweight, affordable durability for hobby use

📱 Consumer Electronics

- Fiber Grade: Lower strength (T300–T400 is enough)

- Weave: 2×2 twill or plain weave for premium look

- Core: Thin laminates only

- Why: Style and lightweight feel > structural strength

📊 Quick Comparison Chart

✅ Takeaway: Carbon fiber is the same material, but its role changes by industry.

- Drones: rigidity + weight balance

- Automotive: weight savings + style

- Sports: lightweight performance

- Marine: corrosion resistance

- RC: affordable durability

- Electronics: sleek aesthetics

That’s the beauty of composites: one material, countless solutions.

💬 What about you? Which industry are you in, and how are you using carbon fiber?

Did you know that even within the same industry, carbon fiber can vary depending on different positions or components? One part might need high stiffness, another high impact resistance, and yet another might prioritize aesthetics.

At PCX Composite, we help companies choose the right carbon fiber for each application. Let’s talk and find the best solution for your project.