Les fournisseurs affirmeront toujours que leur fibre de carbone est de qualité supérieure, mais la vérité est que…, Le meilleur moyen de le savoir est de le vérifier soi-même.. Même des fibres d'apparence similaire peuvent présenter de grandes variations en termes de résistance, de rigidité et de consistance.

Voici Conseils pratiques pour inspecter vous-même la qualité de la fibre de carbone :

1. Qualité de la fibre

Fibre de carbone de haute qualité utilise notes réputées comme les fibres T300, T700, T800 ou à module supérieur. La qualité de la fibre détermine résistance, rigidité et résistance à la fatigue, mais il ne peut être identifié simplement en regardant le tissu ou la partie finie.

Conseil: La méthode la plus fiable pour vérifier la qualité de la fibre est de tester le matériau dans des conditions d'application réelles, tels que des tests de charge, de contrainte ou de flexion, afin de garantir qu'il réponde à vos exigences de performance.

2. Cohérence du tissage

La bonne fibre de carbone a des tissages réguliers et serrés sans interstices, fibres mal alignées ni effilochages. Un matériau de mauvaise qualité peut présenter des motifs inégaux, des fils lâches ou un espacement irrégulier.

Conseil: Inspectez visuellement les deux faces du tissu ou de la pièce finie.

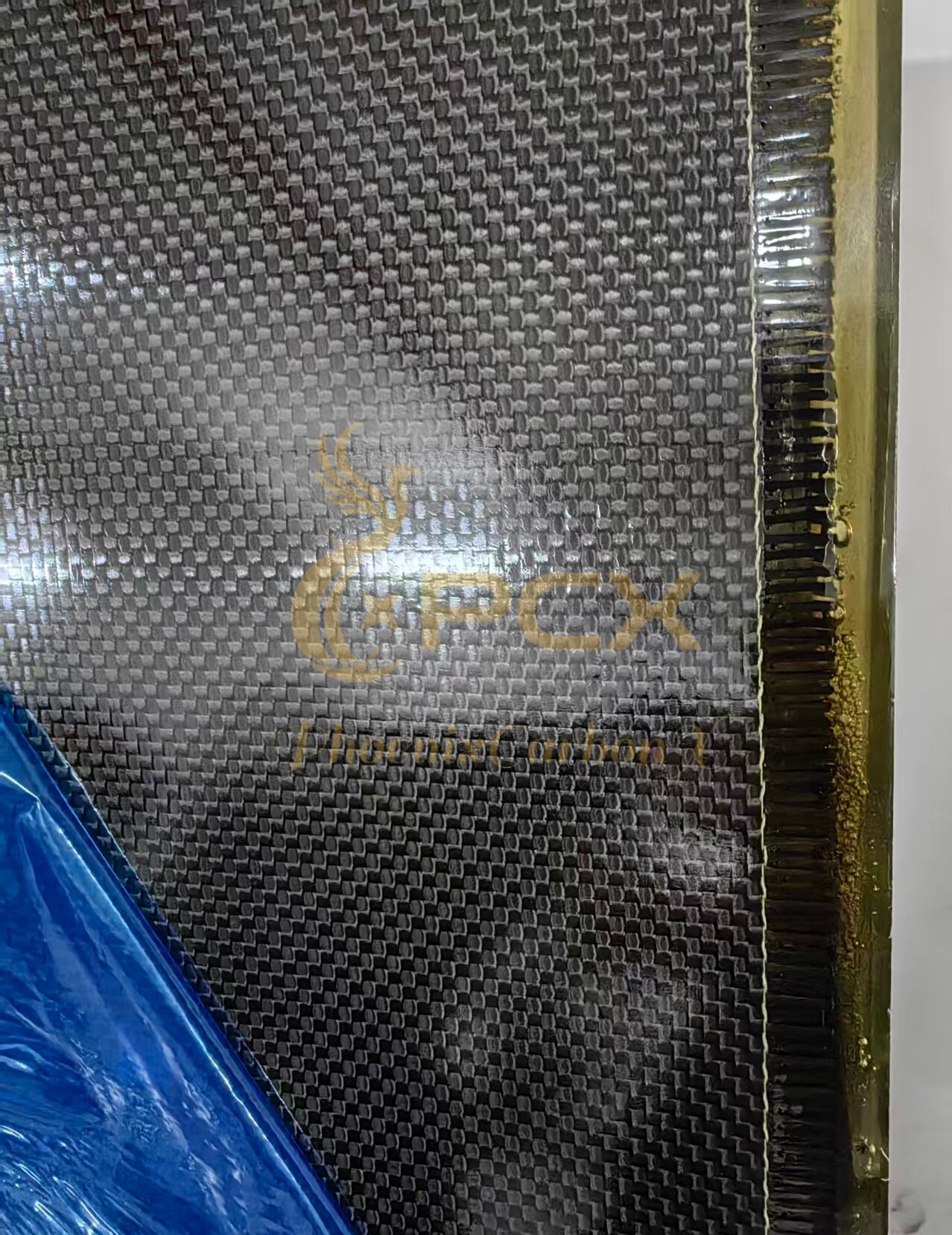

3. Qualité de surface

La fibre de carbone haut de gamme a souvent finitions lisses et sans défaut. Des surfaces rugueuses, des bulles ou une décoloration peuvent indiquer une mauvaise manipulation ou une résine de mauvaise qualité.

Conseil: Passez légèrement vos doigts sur la surface et inspectez-la sous un bon éclairage pour repérer les bosses, les bulles ou un brillant irrégulier.

4. Imprégnation de résine

Pour la fibre de carbone pré-imprégnée, assurez-vous de La résine est répartie uniformément.. Une résine irrégulière peut créer des zones fragiles après durcissement. Les tissus secs doivent également présenter une épaisseur et une texture homogènes.

Conseil: Vérifiez l'épaisseur et le toucher uniformes du tissu ; une résine irrégulière ou des zones sèches peuvent indiquer une mauvaise qualité.

5. Tests de performance

Si possible, test a petit échantillon avant de s'engager sur une commande plus importante. Des vérifications simples comme le pliage, la flexion ou la pesée du matériau peuvent révéler les points faibles ou les incohérences.

Conseil: Même un test pratique rapide peut montrer si le matériau sera performant dans votre application réelle.

✅ Points clés à retenir : Au lieu de faire aveuglément confiance aux fournisseurs, Faites confiance à ce que vous pouvez inspecter et tester vous-même.. Une fibre de carbone de bonne qualité présente une trame, une finition de surface, une répartition de résine et des performances vérifiées homogènes.

💬 Étape suivante : Voyez-le. Touchez-le. Testez-le. Obtenez des échantillons de fibre de carbone depuis PCX Composite et vérifier vous-même la qualité de vos projets.