Carbon fiber plate is widely used because they’re strong, lightweight, and stiff. But while many people think these plates are just layers of woven carbon fiber fabric, the truth is more complex — especially for high-performance or cost-effective plates.

Most normal carbon fiber plates (the kind commonly sold for drones, RC parts, machines, etc.) are made of three key components:

🧱 1. Unidirectional Carbon Fiber Core (UD Layer)

Сайт core of a standard carbon fiber plate is typically made from unidirectional (UD) carbon fiber. In UD fabric, all fibers run in the same direction, which provides maximum strength and stiffness along that direction.

Why use UD in the core?

- Better mechanical performance: UD layers offer higher strength per layer than woven fabrics.

- More efficient layup: You can control the direction of strength by adjusting the orientation of each UD layer (e.g., 0°, 90°, +45°, -45°).

- Экономически эффективный: UD fabric is usually less expensive and easier to work with in large quantities.

👉 In most plates, the core is made of multiple UD layers stacked in alternating directions to balance strength in all directions.

🧪 2. Epoxy Resin System

All the carbon fiber (UD core and woven outer layers) is impregnated with эпоксидная смола, which:

- Binds the fibers together into a solid structure

- Protects the fibers from moisture, UV, and impact

- Gives the final plate its shape and surface

High-quality plates use high-temperature cured epoxy for better strength and heat resistance. Cheaper plates may use low-grade epoxy or polyester resin, which is less durable.

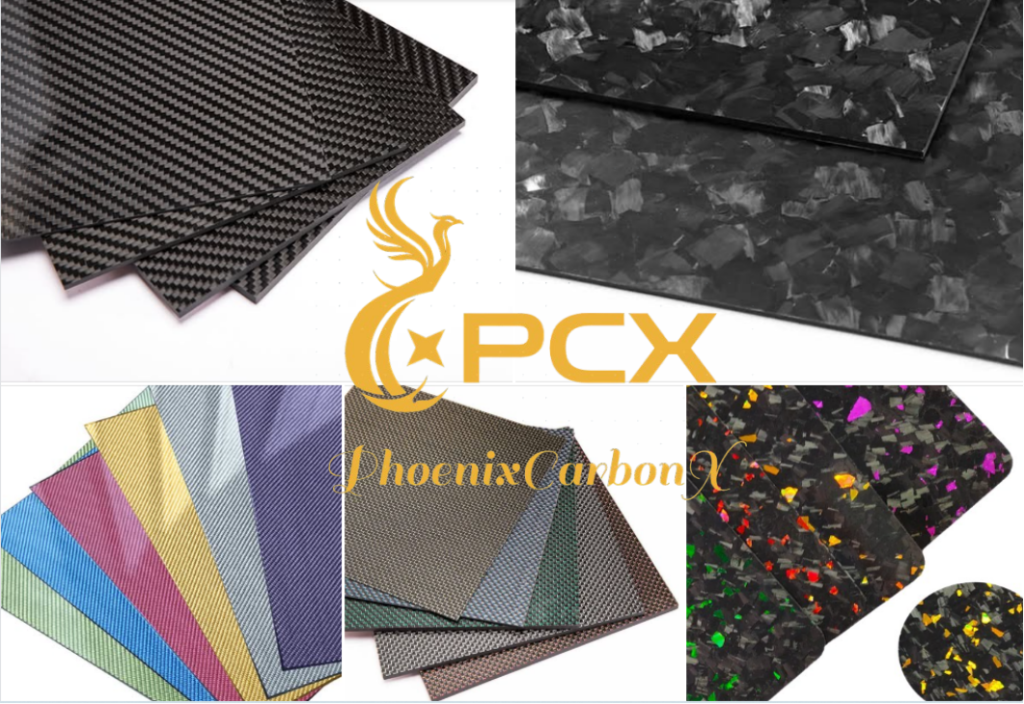

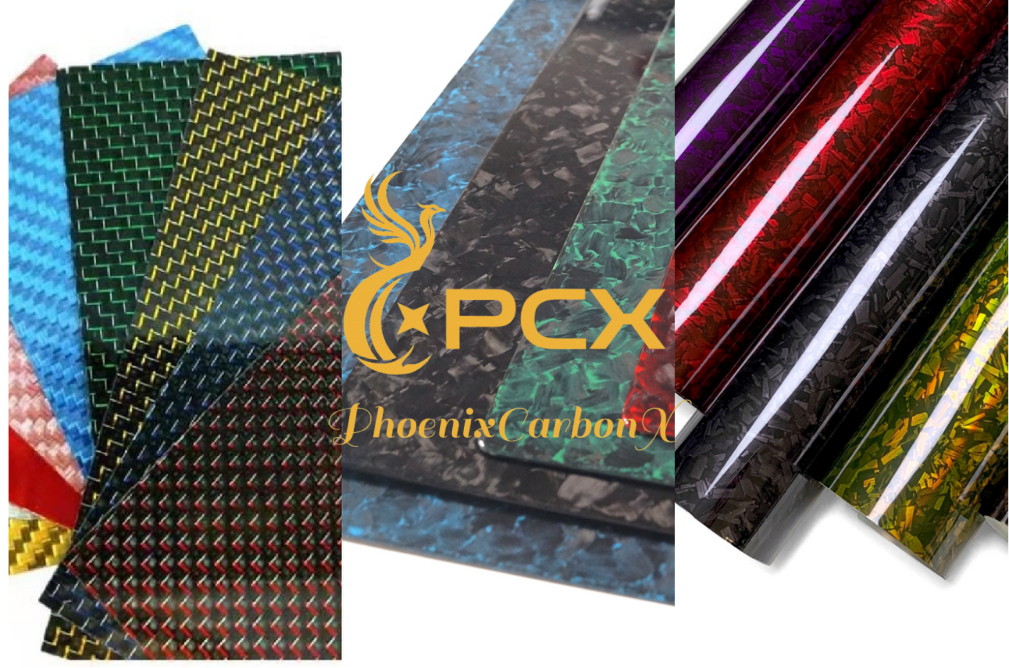

🎨 3. Woven Carbon Fiber Outer Layers (Surface Layers)

On the top and bottom surfaces of the plate, manufacturers typically use woven carbon fiber fabric — usually 3K саржевое переплетение или 3K plain weave.

Why add woven layers?

- Better appearance: The weave looks cleaner and more “premium.”

- Improved surface finish: Smoother, more consistent texture for cutting, bonding, or visual appeal.

- Added strength: The woven layer adds some strength and stiffness, especially in both X and Y directions.

🔹 3K Twill Weave: Most common for its balance of flexibility and a glossy, modern look. 🔹 Плетение 3K: Tighter, more stable, but less shiny.

👉 These woven layers are usually just 1 layer per side — the real structural strength is mostly in the UD core.

📐 Typical Structure of a Carbon Fiber Plate (Example: 3mm Thick)

Here’s what a standard 3mm carbon fiber plate might look like inside:

Top layer: 1x 3K woven twill fabric (cosmetic and light strength)

Middle core: 10–20 layers of UD carbon fiber, oriented at 0°, 90°, ±45°

Bottom layer: 1x 3K woven twill fabric (same as top)

Resin: Impregnated throughoutThis structure gives the plate:

- High strength in multiple directions

- A clean, professional outer finish

- Lightweight and excellent rigidity

⚠️ Not All Plates Are the Same

Some cheaper carbon fiber plates may:

- Use стекловолокно or filler in the core (not full carbon fiber)

- Use low fiber content (more resin than fiber = weaker)

- Have no real woven surface (just printed carbon pattern)

Always check with your supplier about:

- UD core or full woven laminate?

- Fiber content (%)

- Resin type

- Manufacturing process (prepreg vs. wet layup)

✅ Summary: What’s Inside a Quality Carbon Fiber Plate

Understanding what’s really inside a carbon fiber plate helps you choose better — whether you need прочность, лёгкий вес, или aesthetic quality.

Let me know if you’d like this article customized for your product catalog, buyer guide, or a visual version with diagrams!